Packaging Essentials | A Comprehensive Guide to Perfume Pump Manufacturing Processes, Technical Principles, and Procurement Key Points

Packaging Essentials | A Comprehensive Guide to Perfume Pump Manufacturing Processes, Technical Principles, and Procurement Key Points

Introduction:

The perfume pump is a critical precision component in perfume products, directly influencing user experience, shelf life, and brand image. Below, I will detail it across six aspects: definition, functional structure, technical key points, procurement essentials, quality control points, and cost structure.

ONE: Perfume Pump Definition

A perfume pump is a precision mechanical liquid dispensing device specifically designed for highly volatile, high-alcohol-content (typically 70%-95% ethanol), and high-value liquids. It is usually installed at the bottleneck of a perfume bottle. By pressing the actuator, it utilizes the coordinated action of an internal piston, spring, and valves to draw a fixed amount of perfume from the bottle and atomize it into a fine mist.

Its core value lies in: precise metering, effective sealing to prevent volatilization and leakage, creating ideal atomization effects, providing comfortable and smooth pressing feel, and offering good decorative properties.

TWO: Perfume Pump Functional Structure

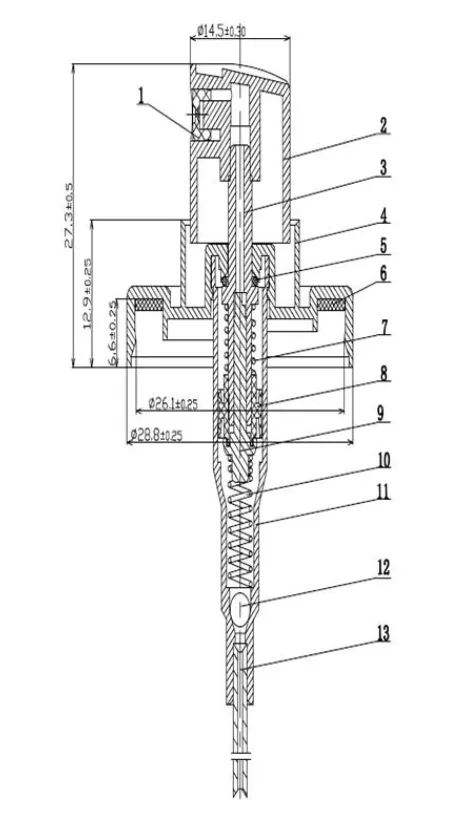

External/User Interaction Parts:

Actuator/Nozzle: The part pressed by the user, typically featuring a fine atomization orifice internally, responsible for dispersing the liquid into mist. Materials often include plastics (ABS, POM, AS, etc.) or metals (gold-plated, chrome-plated, etc.), with surfaces treated via electroplating, coating, UV, etc., for decoration.

Outer Sleeve/Decorative Cap: Covers the pump body externally for protection and aesthetics; materials and processes vary, serving as a key embodiment of brand design.

Pump Body Core/Functional Parts:

Inlet Ball Valve: Located at the dip tube bottom or pump body base, allowing liquid entry from the bottle only, preventing backflow. Usually glass beads (inert) or solvent-resistant plastic beads (e.g., PP), working with the valve seat.

Outlet Ball Valve/Sealing Bead: (In some designs) Located in the piston or stem, sealing the outlet channel in non-pressed state to prevent air entry and perfume volatilization. Opens during pressing to allow liquid flow.

Pump Chamber/Cylinder: The core working cavity with precise piston movement inside. Materials require high chemical resistance (e.g., PP, PE, PCTG, POM, glass). The inner wall demands extremely high smoothness.

Piston: Performs reciprocating motion in the pump chamber to generate suction and pressure. Typically made from solvent-resistant rubber (e.g., EPDM, FKM fluororubber) or special plastics (e.g., POM), tightly fitting the chamber wall for sealing.

Piston Rod/Valve Stem: Connects the actuator and piston, transmitting pressing force. Often designed with liquid channels and valve structures internally. Materials mostly POM or stainless steel.

Spring: Provides rebound force for the actuator and assists piston reset. Material must be highly corrosion-resistant (usually 302/304 stainless steel), with its elasticity directly affecting pressing feel and rebound speed.

Ball Valve/One-Way Valve:

Inlet Ball Valve: Located at the dip tube bottom or pump body base, allowing liquid entry from the bottle only, preventing backflow. Usually glass beads (inert) or solvent-resistant plastic beads (e.g., PP), working with the valve seat.

Outlet Ball Valve/Sealing Bead: (In some designs) Located in the piston or stem, sealing the outlet channel in non-pressed state to prevent air entry and perfume volatilization. Opens during pressing to allow liquid flow.Valve Seat: Cooperates with the ball valve to form a sealing surface. Material needs corrosion resistance and moderate hardness (e.g., POM).

Dip Tube: Inserted to the bottle bottom to guide liquid into the pump chamber. Materials mostly PP or PE. Length must match the bottle shape, often with a slanted or notched end for better suction.

Fixing and Sealing Parts:

Gasket/Sealing Ring: Positioned between the pump body and bottle mouth to ensure bottleneck sealing, preventing leakage and volatilization. Materials mostly EPDM or FKM fluororubber, requiring high resilience and low permanent compression set.

Lock Cap/Fixing Ring: Usually aluminum or plastic, mechanically securing the pump body to the bottle mouth (via screwing or crimping) and compressing the sealing gasket.

THREE: Perfume Pump Technical Key Points

Material Compatibility: All parts contacting perfume (pump chamber, piston, ball valve, valve seat, dip tube, gasket) must withstand long-term exposure to high-concentration alcohol, fragrance compounds (possibly containing esters, aldehydes, etc.), and solvents without swelling, dissolving, cracking, leaching, or chemical reactions.

Sealing Performance:

Static Sealing: The bottleneck gasket must effectively seal the bottle mouth.

Dynamic Sealing: Sealing between piston and pump chamber wall is crucial, maintaining integrity during long-term reciprocating motion to prevent alcohol volatilization and fragrance loss.

Valve Sealing: Inlet and outlet valves (if present) must close tightly in non-working state, isolating air entry and liquid volatilization. Fluorination treatment is often used to enhance sealing surface inertness and effectiveness.

Atomization Performance: Nozzle orifice size, internal vortex structure design, and liquid pressure together determine the mist fineness, uniformity, cone angle, and atomization form (e.g., fan-shaped, conical). It must achieve the consumer-expected "mist-like lightness" effect.

Metering Accuracy and Consistency: The liquid amount dispensed per press (typically 0.05ml - 0.2ml) must be precise and stable, with minimal batch-to-batch variation.

Pressing Feel: Spring force and friction design must be balanced to provide smooth, effortless, quick-rebounding, and "premium" pressing experience. Stroke and actuation force are key parameters.

Volatilization Resistance/Fragrance Preservation: This is the core distinction from ordinary pumps. Achieved through multi-layer sealing designs, high-quality sealing materials (especially fluororubber), valve seals, and sometimes inert gas filling or special vacuum designs in the pump to minimize headspace air, delaying perfume oxidation and volatilization.

Compatibility and Adaptability: Pump dimensions (especially bottleneck thread specs) and dip tube length must perfectly match the bottle type. Output volume must suit the perfume's viscosity and surface tension.

Physical and Chemical Stability: After long-term storage, components must not deform, age, or fail (e.g., springs), and liquid must remain uncontaminated.

FOUR: Perfume Pump Procurement Essentials

Define Requirements: Determine the needed pump type (e.g., spray volume, mist form, actuator style, decoration requirements), material grade, sealing level (standard/high fragrance-preserving), bottleneck size, and target cost.

Supplier Qualification Review:

Professional Experience: Specialized or rich in high-end perfume pump manufacturing?

Technical Capabilities: Complete in material R&D, mold precision, automated production, testing equipment (especially sealing and atomization tests)?

Quality System: Certified under ISO 9001, ISO 22716 (GMP for Cosmetics)?

Compliance: Materials meet regulations (e.g., REACH, RoHS, FDA contact requirements)? Complete safety data sheets and conformity declarations?

Capacity and Supply Chain Stability: Able to ensure stable supply and delivery?

Sample Evaluation: Strict Testing:

Compatibility Testing: Fill pump with actual perfume formula, store under accelerated aging conditions (e.g., 40°C/75%RH) for 1-3 months or longer, observe component changes, liquid stability (turbidity, precipitation, discoloration, odor changes), and pump function.

Sealing Testing: Weight loss method (weigh filled bottle over time for losses), vacuum hold test (simulate air transport low pressure), inversion leak test, etc.

Functional Testing: Spray volume precision and consistency, mist form observation, pressing feel assessment, rebound speed, priming test (ability to re-suction).

Physical Testing: Spring force, component dimensional accuracy, appearance inspection (burrs, scratches, plating/coating quality).

Supplier Collaboration and Communication: Confirm technical response speed, problem-solving ability, customization development, minimum order quantity, delivery lead time.

Cost and Commercial Terms: Compare prices while meeting quality and functional requirements. Consider total cost of ownership (including potential quality risk costs).

FIVE: Perfume Pump Quality Control Points

Incoming Inspection: Strictly inspect all raw materials (plastic pellets, rubber, spring steel, glass beads, metal parts) for material certificates, dimensions, appearance, and key properties (e.g., rubber solvent resistance, compression set).

Process Control:

Injection/Molding: Control temperature, pressure, time, etc., to ensure component dimensional accuracy, no flash, no shrinkage, smooth inner walls.

Assembly: Conduct in clean rooms (at least Class 100,000), avoiding contamination. Focus on key stations (e.g., piston insertion, valve assembly). Use automation for consistency and efficiency.

Spring Force Detection: Inline or offline sampling for spring elasticity.

Inline Functional Testing: Basic function tests per pump or batch (e.g., smooth pressing, liquid output).

Outgoing Inspection:

Appearance Check: Full or AQL sampling for defects (stains, scratches, deformation, poor plating).

Dimensional Check: Sampling key dimensions (e.g., bottleneck fit, total height).

Performance Sampling:

Spray Volume Test: Press specified times (e.g., 10), collect and weigh total output, calculate average per press against specs.

Sealing Test: Often vacuum hold method: Install pump on test bottle with specific liquid, evacuate to negative pressure (simulate air transport), hold and observe pressure decay or leaks. Weight loss method also common (initial weigh, store inverted/upright, re-weigh).

Mist Mode Check: Visual or analyzer for shape, uniformity, no dripping.

Pressing Feel Assessment: Sampling for stroke, actuation force, rebound.

Batch Traceability: Ensure each pump or batch has clear identification, traceable to raw material batches, production dates, lines, etc.

Stability Monitoring: Regularly conduct long-term storage stability tests.

SIX: Perfume Pump Cost Structure

Perfume pump costs are relatively complex, heavily influenced by brand positioning (luxury vs. mass-market), design complexity, material selection, purchase volume, automation level, etc. Approximate ratios (for reference):

Raw Material Costs:

Plastic Pellets (30-40%): For pump body, actuator, sleeve, dip tube, etc. Chemical resistance grade (e.g., PCTG vs. PP), transparency, special color masterbatch affect costs.

Metal Parts (15-25%): Spring (core cost, high-quality stainless), lock cap (aluminum or steel), decorative metal actuator/sleeve (gold/chromium plating).

Rubber/Elastomers (10-20%): Piston, sealing gasket. High-performance fluororubber costs far more than standard EPDM.

Others (5-10%): Glass beads (ball valve), packaging materials (liners, turnover boxes), etc.

Manufacturing and Processing Costs (20-35%):

Injection/Molding: Mold costs (high-precision expensive, amortized), equipment depreciation, energy, labor.

Secondary Processing: Electroplating, coating, UV layers, laser engraving, etc., for decoration – higher costs.

Assembly: Labor or automated equipment costs. Clean room maintenance.

Fluorination Treatment: Key for enhanced sealing, adds significant cost.

Quality Control and Testing Costs (5-15%): Testing equipment investment (e.g., auto-testers, atomization analyzers), inspection labor, lab tests (compatibility, stability), quality staff costs.

R&D and Mold Amortization (5-15%): New pump type structural design, mold development (hundreds of thousands to millions RMB) amortized per unit. Higher customization increases this share.

Management, Profit, and Logistics (15-30%): Enterprise overheads, supplier profits, transport and storage costs.

Summary of Key Cost Drivers

High-Performance Materials: Fluororubber piston/gasket > EPDM; PCTG/POM body > PP; 304 stainless spring > ordinary steel.

Complex Structures and Decorations: Multi-layer plating, special surface effects (matte, pearlescent), irregular actuator designs.

Ultra-High Sealing/Fragrance Preservation Requirements: Need more complex designs, precise processing, strict testing (e.g., vacuum filling tech).

Purchase Volume: Larger volumes lower per-unit costs (amortize molds/fixed costs).

Automation Level: High automation lines have high initial investment but improve consistency and reduce labor long-term.

SEVEN: Perfume Pump Trends

Sustainability: Use of recycled materials (PCR), recyclable designs, reduced component counts, lightweighting.

Replaceable Cores: Designs supporting inner core replacement to reduce packaging waste.

Customization and Differentiation: Unique actuator designs, innovative surface treatments, brand-exclusive elements.

Higher Fragrance Preservation Tech: Continuous improvements in sealing materials and structures to extend shelf life and user experience.

Smart Pump Prototypes: Exploring integrated micro-sensors or chips for anti-counterfeiting, usage tracking, etc. (still early stage).

Conclusion:

Though small, the perfume pump integrates precision mechanics, materials science, chemical engineering, and aesthetic design, making it an indispensable core component for perfume product success. Deep understanding aids brands and manufacturers in making wiser decisions.