Packaging Knowledge | A Comprehensive Introduction to Perfume Bottle Manufacturing Processes, Technical Principles, and Procurement Essentials

Packaging Knowledge | A Comprehensive Introduction to Perfume Bottle Manufacturing Processes, Technical Principles, and Procurement Essentials

Introduction:

Perfume bottles serve as the core carrier for perfume products and a vital component of the sensory experience. Their design, materials, processes, and quality directly determine the product's positioning, perceived value, and market performance. The following analysis systematically breaks down perfume bottle packaging from multiple dimensions as requested.

ONE: Perfume Bottle Materials

The selection of materials for perfume bottles is fundamental, directly impacting texture, cost, protective properties, and sustainability.

Glass: The dominant material, accounting for over 95% of usage.

Types:

Soda-lime glass: Most common, low cost, good transparency, easy to process (blowing, pressing). However, relatively fragile with slightly inferior chemical stability.

High-white or crystal-white glass: Lower iron content, exceptional transparency and whiteness for a purer, upscale appearance. Higher cost than standard soda-lime glass.

Flint glass: Contains lead or barium, high refractive index, crystal-clear and brilliant when cut. Used for luxury perfume bottles. Expensive, with environmental concerns (lead).

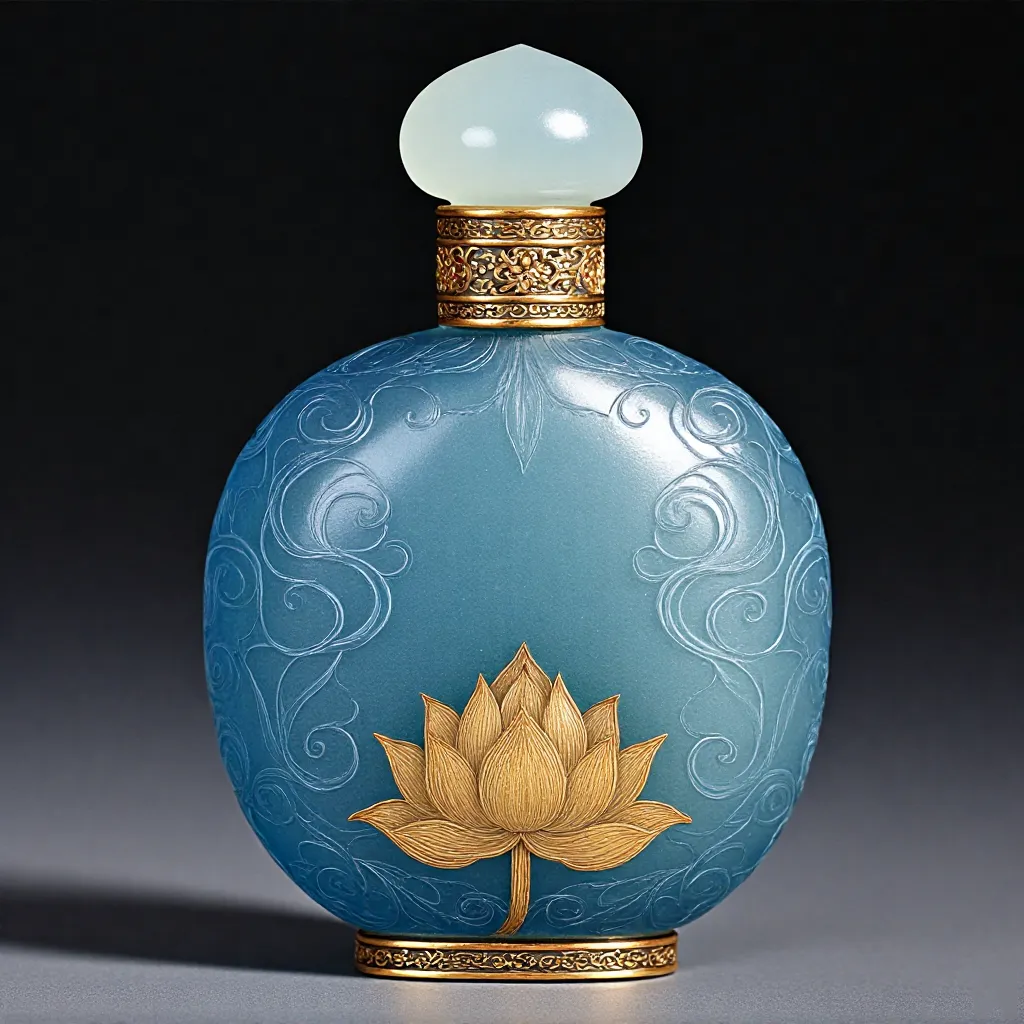

Colored glass: Created by adding metal oxides (e.g., cobalt for blue, chromium for green, selenium for red). Protects perfume from UV light (crucial for light-sensitive fragrances) and enhances aesthetics.

Coated or plated glass: Base glass sprayed with color lacquer or PVD vacuum-coated (e.g., gold, rose gold, gunmetal) for metallic textures or special colors.

Types:

Advantages: Chemical inertness (no reaction with perfume ingredients), high transparency, premium feel, strong moldability (various complex shapes), recyclable (eco-friendly).

Disadvantages: Fragile, heavy, high transportation costs.

Plastic: Primarily for travel sizes, samples, mid-to-low-end perfumes, or certain caps/accessories.

Types:

PETG: Good transparency, high toughness, decent chemical resistance; often for travel spray bottles.

PMMA (acrylic/organic glass): Extremely transparent, hard, glossy; substitutes glass in mid-to-high-end designs for bodies or caps. Higher cost.

ABS: High strength, easy to process (injection molding); for complex caps, bases, decorations. Can be electroplated.

Others (PE, PP): For protective liners, droppers, non-contact parts.

Advantages: Shatter-resistant, lightweight, low cost (some), high design flexibility (injection molding).

Disadvantages: Generally inferior transparency/texture compared to glass (except PMMA), potential minor permeation or reactions on long contact (requires strict selection/testing), some plastics poor for environment (hard to degrade).

Metal: For caps, decorative rings, nozzles, or rare special bodies (e.g., aluminum cans).

Zinc alloy: Most common, easy die-casting, various surface treatments (plating, coating), moderate cost, good texture.

Aluminum alloy: Lightweight, anodizable for colors (like iPhone casing feel); for premium caps or bodies.

Stainless steel: Strong corrosion resistance, high strength; for nozzle springs, beads, some premium caps.

Copper/brass: For luxurious vintage cap decorations or plating bases.

Types:

Advantages: High strength, versatile textures (via treatments), good protection (caps).

Disadvantages: Higher cost (especially aluminum, stainless), prone to scratches, some metals may corrode (needs treatment).

Others: Wood, ceramic, stone for special limited editions or artistic bottles; very high cost, complex processes.

TWO: Perfume Bottle Processes

Perfume bottle manufacturing involves various precise techniques to shape the final form and effects.

Glass Body Forming:

Pressing: Molten glass injected into mold, pressed down. High efficiency for standard shapes (cylindrical, square), thicker walls, possible mold lines.

Blowing:

Manual blowing: Artisans use blowpipes for small batches, artistic, complex irregular shapes. High cost, variations per piece.

Machine blowing: Highly automated, large output, good consistency. Produces relatively complex shapes; mainstream method.

Molding:

Cutting and engraving: For crystal or high-value glass, creating faceted refraction. Manual or CNC.

Fire polishing: High-heat treatment for smooth, rounded edges like bottle mouths.

Surface Finishing:

Coating: External spraying (solid colors, gradients, pearlescent, metallic), rubber oil (non-slip), UV gloss (brightness, wear resistance).

Plating: For metal (zinc caps) or plastic (ABS caps) via water electroplating (chrome, nickel, gold, rose gold) or eco-friendly PVD.

Screen printing/hot stamping: For logos, patterns, text on bodies. Hot stamping (gold/silver) appears upscale.

Frosting/acid etching: Matte, frosted glass surfaces or etched patterns.

Laser engraving/marking: Precise permanent marks (batch numbers, logos) on glass/metal.

Cap/Nozzle Assembly:

Injection molding: Main for plastic caps, nozzle shells, internal parts.

Die-casting: Primary for zinc alloy caps.

Mechanical assembly: Precise integration of springs, beads, seals, valves, straws into nozzle systems. Automation key.

THREE: Perfume Bottle Technologies

Precision Mold Technology: Foundation for high-quality glass bottles and complex plastic/metal parts. High-precision, long-life, easy-release molds are essential.

Automated Production and Inspection: High-speed glass formers, auto-coating lines, assembly lines boost efficiency/consistency. Machine vision (AOI) detects defects (bubbles, stones, cracks, deformations), dimensions, print quality, nozzle functions online.

Eco-Friendly Surface Treatments: PVD over traditional electroplating, water-based over oil-based paints to reduce VOC emissions/pollution.

Sealing Technology: Internal seals (silicone, butyl) and valve designs critical for leak-proof, non-volatile, smooth spraying. Ethanol resistance testing key.

Filling and Capping Technology: High-precision, non-contact auto-filling lines (minimize contamination), capping equipment ensuring seal/torque consistency.

FOUR: Perfume Bottle Quality Control Points

QC for perfume bottles is rigorous throughout the supply chain.

Incoming Inspection (IQC): Dimensions, appearance, materials, performance (e.g., seal chemical resistance) for glass blanks, plastic pellets, metal ingots, plated parts, seals, nozzle assemblies.

In-Process Inspection (IPQC):

Glass: Forming dimensions, wall uniformity, mold lines, stones, bubbles, cracks.

Coating/Plating: Adhesion (cross-cut test), wear (RCA), color variance, gloss, thickness, corrosion (salt spray).

Printing: Position accuracy, color, clarity, wear.

Assembly: Nozzle function (spray volume, atomization, sealing), cap fit, tightness (torque test).

Final Inspection (FQC/OQC):

Sealing: Vacuum/pressure leak tests (no leaks/volatilization).

Nozzle: Spray pattern, volume per spray, actuation pressure, durability (press count test).

Compatibility: Long-term storage tests ensuring no reactions, discoloration, harmful leachates from glass/plastic/metal/seals with perfume.

Drop test: Simulate transport/use impact resistance (especially glass).

Chemical stability: Glass internal pressure test (for aerated perfumes).

Appearance: No scratches, stains, impurities; uniform color, clear printing.

Dimensions: Per drawing tolerances (height, diameter, mouth size).

Performance:

Lab Testing: Material composition, heavy metal migration (REACH, RoHS), volatiles, odor (no transfer to perfume).

FIVE: Perfume Bottle Cost Structure

Costs are complex, influenced by multiple factors.

Main Components:

Materials (30-60%): Glass (crystal-white > high-white > soda-lime), metals (aluminum > zinc > stainless), plastics (PMMA > PETG > ABS), plating/coating, seals.

Molds (amortized): For glass, plastic/metal injection/die-casting. Higher complexity = pricier; small batches increase per-unit share.

Processing (20-50%): Glass forming (manual blowing >> machine > pressing), surface (PVD > electroplating > coating; frosting > plain), printing/stamping, assembly (nozzle complexity impacts).

QC: Equipment, labor, lab tests.

Packaging/Logistics: Liners (foam, card), boxes, transport (glass heavy/fragile = high cost).

Key Influences:

Complexity: Irregular > regular; multi-layer treatments > single; complex nozzles > simple; manual > machine.

Material Grade: Crystal glass > crystal-white > soda-lime; PMMA > PETG; aluminum > zinc.

Volume: Larger orders lower mold/processing per-unit costs.

Quality Standards: Tolerances, defect acceptance (AQL) affect yield/cost.

Surface Treatments: PVD, complex coatings, frosting add significantly.

Origin: Labor (China < Europe), logistics distance.

SIX: Perfume Bottle Procurement Essentials

Define Needs and Specs: Create detailed Technical Data Sheet (TDS) and Packing Standard: Materials, dimensions, tolerances, appearance, performance (sealing, spray), tests, eco-requirements (RoHS, REACH, recyclability). Specify shape, color (Pantone), logo positions/crafts.

Supplier Selection/Evaluation:

Core Capabilities: Expertise/equipment in glass forming, specific treatments (PVD, complex coating), nozzle assembly, mold development.

Quality Systems: ISO 9001 baseline; robust QC labs/processes (compatibility/sealing tests).

Capacity/Delivery: Meet volumes/urgents. Glass cycles long (esp. molding).

Cost Competitiveness: Holistic quotes; consider mold share, MOQ, terms.

Sustainability: Eco-policies, recycled glass use.

Experience/Communication: Responsiveness, problem-solving, sampling cooperation.

Mold Management: Clarify ownership (usually brand), fees. Standardize design, acceptance, maintenance, storage. Retain drawings/revision records.

Sampling and Confirmation:

Proto Samples: Validate design feasibility/structure.

Pilot Run Samples: Small-batch for production process/stability.

First Article Inspection (FAI): Full check of initial production against specs.

Filling Tests: Use final perfume formula for long-term compatibility and line fit.

Pricing Negotiation/Contract Management: Negotiate via cost analysis (materials, processing, molds). Define adjustment mechanisms (raw material fluctuations). Rigorous contracts on specs, standards, acceptance, liabilities, IP (designs).

Production/Delivery Monitoring: Require plans. Conduct DUPRO inspections for mid-process issues. Strict OQC per AQL.

Inventory/Logistics: Fragile glass needs shockproof liners/boxes. Balance safety stock vs. costs/risks. Optimize shipping to cut damage/costs.

Risk Management:

Supply Chain: Key materials (rare oxides), single-supplier dependency.

Quality: Tight controls to avoid recalls (e.g., poor sealing/volatilization, impure glass breakage).

Cost: Material/Exchange rate fluctuations (imports).

IP: Patent unique designs.

Summary

Perfume bottles are precise products blending art, craft, and technology. Key aspects include:

Glass dominance: Pursuing higher transparency (crystal-white), refined treatments (PVD, special coatings), complex forming (irregular, thin-walled).

Nozzles as essence: Spray experience (fine atomization, feel, quietness) and sealing reliability as technical barriers.

Texture and Differentiation: Via material mixes (glass+metal+special plastics), multi-layer treatments for unique visual/tactile experiences.

Sustainability: Increasing recycled glass, lightweight designs, eco-materials (water-based paints, PVD), simplified packaging, better recyclability as trends.

Intelligence/Interaction: NFC/QR for anti-counterfeit, traceability, storytelling, marketing emerging.

Cost Pressures/Efficiency: Automation, smart manufacturing, supply chain optimization key for control. Successful procurement/management requires close collaboration between brand (market, R&D, procurement, quality) and suppliers (design, engineering, production, quality) to balance aesthetics, feasibility, strict QC, and cost-effectiveness. Extreme attention to detail defines the industry.